DIY-P1100

Perkins

DIY-P1100

1100kVA / 880kW

1000kVA / 800kW

50Hz-1500RPM

Perkins 4008TAG2A

Leroy-Somer TAL-A49-E

| Availability: | |

|---|---|

| Quantity: | |

Diesel, 50HZ, 380-440V

Powered by: Perkins

Leroy-Somer

PRP | ESP | |

POWER KVA | 1000 | 1100 |

POWER KW | 800 | 880 |

Generator Structure | Dimension | Weight | Noise Level |

Type | (mm) | (Kgs) | dBA@7m |

Open Frame | 4700*2100*2370 | 8700 | 90 |

Soundproof | 20GP Container | 11750 | 80 |

Super Silent | Optimize Customized | / | 65 |

Compact Structure

The canopy generators are designed for optimum sound attenuation and sized for easy transport while maximizing cooling air flow & anti vibration throughout the genset.

High Quality Steel and Paint Craftwork

The canopies are made of high-quality cold-rolled steel with powder coating technique while makes the surface durable, corrosion and scratch resisting

Advanced Rainproof and Dustproof Design

The control panel, maintain doors and canopy board adopt rainproof design with protection at IP56 class which effectively stop rain and dust's intrusion.

Control system and cable output terminal separated, safety and better for operation, rodent-resistant net installation.

Environmental

l Multiple noise reduction configuration can reduce the noise level by 15-35 dab(A). The silent type Genset is lower noise control, with 75dba@7meter. This canopy design makes the generator set ideal for working during evening, residential area or in the environments which requires super silence.

Super silent canopy design optional.

l Super low emission.

Easy To Operate

l All DIYPOWER canopy are with 6 doors and LED light inside, which is better for after service maintenance.

l CONTROL SYSTEM

Intelligent control module with multiple languages

l SIMPLE FUEL AND WATER REFILLING

External fuel refilling inlets; base fuel tank install two air breathing holes.

Base fuel tank keep 8~10 hours on 100% loading;

Radiator access is located on the top of canopy for ease of coolant filling.

With 24V free-maintenance "VARTA" battery

Engine:

Water jacket heater/Fuel Heater/Oil Heater/Oil Temp Sensor/Fuel Level Sensor

Alternator:

PMG / AREP/Space Heater

Control system:

ATS / Automatic Transfer Switch/Paralleling Cabinet

Genset:

Big Base Fuel Tank/External independent fuel tank/Super Silent Canopy

Spare Parts:

FUEL FILTER/OIL FILTER/AIR FILTER/FAN BELT/GASKET - CYLINDER HEAD/SEAL - CYL HEAD COVER/SEAL-ROCKER BOX/GASKET - TIMING CASE/GASKET - TIMING CASE COVER/GASKET - WATER PUMP/FRONT OIL SEAL/REAR OIL SEAL

Engine Manufacture | UK Perkins |

Engine Model | 4008TAG2A |

Number of Cylinders | 8L |

Air intake way | Turbocharged and air to air |

Bore × stroke | 160mm X 190mm |

Compression Ratio | 13.6:1 |

Displacement | 30.561L |

Engine Standby Output | 985KW(50HZ) |

Engine Prime Output | 899kW |

Fuel Consumption at 100% Output (Standby) | 240L/h |

Fuel Consumption at 100% Output (Prime) | 215L/h |

About Perkins

With a history stretching back more than 85 years, Perkins is one of the world’s leading providers of diesel engines. We aim to set standards of engineering excellence, providing the most comprehensive range of innovative and reliable power solutions, tailored to meet the precise requirements of our customers.

General characteristics – 6 & 12 wire

Insulation class | H | |

Winding pitch | 2/3 6or 12 | |

Number of wires | 2/3 (wind.6S - 6-wire / wind.6 - 12-wire) | |

Protection | IP23 | |

Altitude | ≤1000m | |

Overspeed | 2250 R.P.M. | |

Air flow 50 Hz(m3/s) | 1 | |

Air flow 60 Hz(m3/s) | 1.2 | |

AREP Short-circuit current=2.7 In: 5 second | ||

Excitation system 6 wires | SHUNT | AREP |

AVR type | R150 | R180 |

Excitation system 12 wires | SHUNT | AREP |

AVR type | R250 | R180 |

Voltage regulation(") | ±1% | |

Total Harmonic distortion THD(*") in no-load | <3.5% | |

Total Harmonic distortion THD(**) in linear load | <5% | |

Waveform: NEMA=TIF(") | <50 | |

Waveform: I.E.C.: FHT(") | <2% | |

Ratings 50 Hz-1500 R.P.M.-6& 12-wire

kVA/kW-P.F.=0.8 | ||||||||||||||

Duty/T°C | Continuous/40℃ | Stand-by/27℃ | ||||||||||||

Class/T°K | H:125K | H:163K | ||||||||||||

Phase | 3ph. | 1ph. | 3ph. | 1ph. | ||||||||||

Y | 380V | 400V | 415V | 440V | 380V | 400V | 415V | 440V | ||||||

△ | 220V | 230V | 240V | 230V | 220V | 230V | 240V | 230V | ||||||

YY | 190V | 200V | 208V | 220V | 190V | 200V | 208V | 220V | ||||||

△△ | 230V | 230V | ||||||||||||

TALA49E | kVA | 1000 | 1000 | 1000 | 950 | 1100 | 1100 | 1100 | 1045 | |||||

kW | 800 | 800 | 800 | 760 | 880 | 880 | 880 | 836 | ||||||

Compliance with internationally recognized standards

Compliance with internationally recognized standards

4 Pole Alternators are in compliance to the main international standards and regulations:

-IEC 60034, NEMA MG 1.32-33, BS 5000 Part 99, VDE 0530, ISO 8528/3, UL 1446, UL 1004 on

request and depending on voltages, marin regulations, etc. It can be integrated into a CE marked

generator.

Alternators are designed, manufactured and marketed in an ISO 9001 and ISO14001 environments

Electrical design

● The alternators are IP 23

● Class H insulation

● Low voltage winding

● 4-terminal plate

● Optimized performance

Robust design

● Compact and rugged assembly to withstand engine vibrations

● Steel frame

● Aluminum flanges and shields

● Single-bearing design to be suitable with most diesel engines

● Sealed for life bearing

● Direction of rotation: clockwise

Integrating digital, intelligent and network techniques are used for automatic control system of diesel generator. It can carry out functions including automatic start/stop, data measure and alarming.

AMF Function:

Upon detection of a mains (utility) failure the module automatically starts the generating set. Once the mains (utility) power has been restored it instructs the generating set to stop.

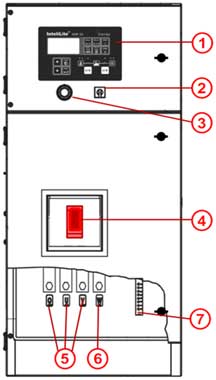

1. Control Module: MRS10, AMF9, DSE7320 for standard controller

~ MRS16, AMF25, DSE7420 for optional

2. DC Power Switch for control system

3. Emergency Stop Button

4. Breaker Handle & Window for operated from outside

5. U/ V/ W Live wire terminals (Copper Bars)

6. N Neutral wire terminals (Copper Bar)

7. (ATS/ Main Power/ Remote Control...etc. ) Signals Access Terminals

Standard Control Panel -ComAp IL3-AMF9

Main Features:

Δ Single gen-set controller for stand-by and prime-power applications

Δ Direct communication with EFI engines

Δ All-in-one intuitive & powerful PC tool for configuration/monitoring/control, locally or remotely

Δ Stand-by and prime-power application in one unit

Δ 5 languages in the controller & Translator functionality, 3 levels of passwords,3 sets of alternative configurations

Δ Magnetic pickup, ECU support & Tier 4 Final ready, 1 slot for plug-in modules

Δ Plug-in module concept for more capabilities (Modbus, Internet, SMS, inputs/outputs)

Δ Power over USB for controller’s adjustment, Adjustable D+ threshold, Ventilation pulse

Δ 6 binary outputs, 6+1 binary inputs, 3 analog inputs,2 high-current binary outputs

Δ E-Stop input physically disconnets binary outputs 1 & 2 from power, Adjustable delay for binary inputs

Δ Alarms and gen-set status asignable to binary outputs

Δ Possibility to select the source for Run Hours, real time clock

Δ Warm-up and cooling functions

Δ Generator C.B. and Mains C.B. control with feedback and return timer

Δ Multi-purpose scheduler functionality, 3 maintenance timers

Δ Detailed history log with up to 150 records, Zero power mode

Δ Start on low battery

Δ Cutout: 172mm x 112 mm (same as IL-NT family)

Other Brands of Control Moudle Opitional

Brand | DEIF | DeepSea | ComAp | ||||||

Model | SGC121 | SGC421 | DSE4620 | DSE6020MKII | DSE6120MKII | DSE7320MKII | AMF9 | AMF20 | AMF25 |

Function | Single-AMF | Single-AMF | Single-AMF | Single-AMF | Single-AMF | Single-AMF | Single-AMF | Single-AMF | Single-AMF |

Certification | CE,UL | CE,UL | CE,UL | CE,UL | CE,UL | CE,UL | CE,UL | CE,UL | CE,UL |

Digital input | 5 | 9 | 4 | 6 | 6 | 8 | 6 | 7 | 8 |

Digital output | 6 | 7 | 6 | 6 | 6 | 10 | 6 | 7 | 8 |

Analog Inputs | 4 | 7 | 3 | 4 | 4 | 6 | 3 | 3 | 4 |

Current monitoring | 3 | 4 | 3 | 3 | 3 | 4 | 3 | 3 | 3 |

Voltage monitoring | 2(32-520V) | 2(32-520V) | 2(26-719V) | 2(26-719V) | 2(26-719V) | 2(26-719V) | 2(100-480V) | 2(100-480V)EU | 2(100-480V)EU |

Preset start/stop cycles | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

cyclic mode | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ |

Multiple sets of protection parameters | ✘ | ✘ | 2 | 2 | 2 | 6 | 3 | 3 | 3 |

Engine injection port | ✔ | ✔ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

USB port | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

RS232 port | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ | ✘ | ✘ | ✘ |

RS485 port | ✔ | ✔ | ✘ | ✘ | ✘ | ✔ | ✘ | ✘ | ✘ |

Ethernet port | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ |

zero sequence current (electronics) | ✘ | ✔ | ✘ | ✘ | ✘ | ✔ | ✘ | ✘ | ✘ |

Reverse time overcurrent | ✘ | ✘ | ✘ | ✘ | ✔ | ✔ | ✘ | ✘ | ✔ |

BTS monitoring | ✘ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ |

Electronic speed control integration | ✔ | ✔ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ | ✘ |

Language Support | ✔ | ✔ | ✘ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ |

Extensions | ✘ | ✘ | ✘ | ✘ | ✔ | ✔ | ✔ | ✔ | ✔ |

Front panel protection class | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 | IP65 |

PLC programming function (M-logic) | ✘ | ✘ | ✘ | ✘ | ✘ | ✔ | ✘ | ✔ | ✔ |

Record of events | 100 | 100 | 50 | 50 | 100 | 250 | 250 | 350 | 350 |

Dimension (LxWxH) | 139x114x38mm | 233x173x39mm | 140x113x43mm | 216x158x43mm | 216x158x43mm | 245x184x51mm | 185x125x47mm | 210x150x47mm | 210x150x47mm |

Hole size (LxW) | 118x93mm | 219x158mm | 118x92mm | 184x137mm | 184x137mm | 220x160mm | 170x110mm | 185x130mm | 185x130mm |

Working temperature | -20-65℃ | -20-65℃ | -30-70℃ | -30-70℃ | -30-70℃ | -30-70℃ | -20-70℃ | -20-70℃ | -20-70℃ |